In the context of glass manufacturing, "gob drop" refers to a specific step in the glass-forming process called the "gob forming" or "gob feeding" stage.

During glass manufacturing, molten glass is gathered from the furnace and shaped into a specific size and weight called a "gob." The gob is a mass of molten glass that will be formed into a final glass product, such as bottles or containers.

The gob drop occurs when the molten glass is released or dropped from the feeder mechanism onto the forming machine. This drop is typically a controlled process, and the timing and speed of the gob drop are crucial for achieving consistent and high-quality glass products.

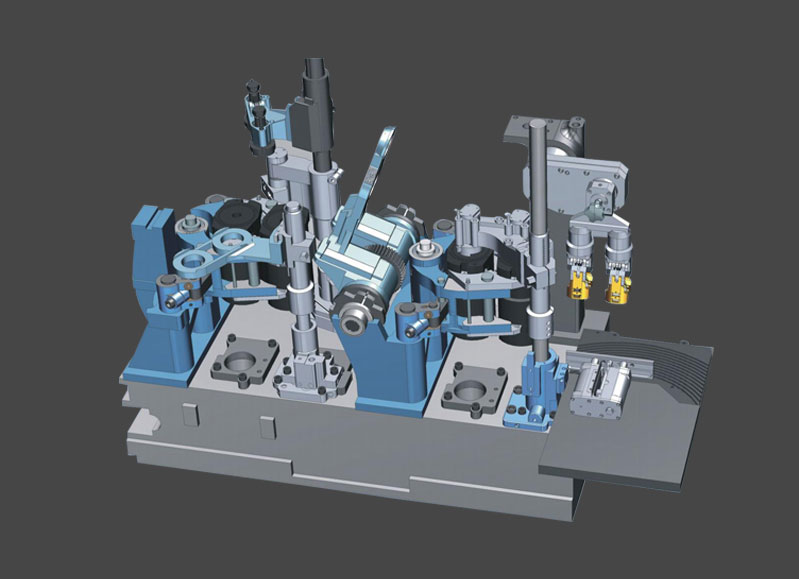

The feeder mechanism, also known as the gob distributor, delivers the molten glass to the forming machine, and the gob drop marks the start of the glass shaping process. The molten glass is dropped onto the blank mold or parison mold, where it begins to take shape according to the specific design and size of the final glass product.

The gob drop needs to be properly synchronized with the operation of the forming machine to ensure accurate and consistent glass production. Factors such as the temperature and viscosity of the molten glass, the design of the forming machine, and the desired product specifications influence the timing and control of the gob drop.

By controlling the gob drop, manufacturers can achieve desired glass thickness, weight, and overall quality in the final product. The gob drop is one of several critical steps in the glass manufacturing process that contribute to the successful production of glass bottles, containers, or other glass products.

In glass manufacturing, the

gob drop process offers several advantages that contribute to the production of high-quality glass products. Here are some key advantages of gob drop:

Controlled glass distribution: The gob drop allows for controlled and precise distribution of molten glass onto the forming machine. This control ensures consistent gob size, weight, and shape, which is crucial for producing uniform glass containers or bottles.

Improved product quality: By controlling the gob drop, manufacturers can achieve greater consistency in the thickness and weight of the glass products. This results in improved product quality and reduces variations that could affect the strength, appearance, and performance of the glass.

Enhanced production efficiency: The gob drop process, when properly synchronized with the forming machine, allows for efficient and continuous glass production. The precise timing and speed of the gob drop contribute to smoother operation and higher production rates, increasing overall manufacturing efficiency.

Reduced waste and cost savings: Accurate gob drop control minimizes glass waste and optimizes material usage. By ensuring consistent gob size and weight, manufacturers can reduce scrap and rework, leading to cost savings in raw materials and production.

Increased flexibility: The

gob drop process offers flexibility in adjusting the size and weight of the glass gobs, allowing manufacturers to adapt to different product requirements. This flexibility enables the production of various glass container sizes and shapes to meet customer demands.

Enhanced glass forming capabilities: The gob drop plays a vital role in initiating the glass forming process. Precise control of the gob drop allows for improved glass shaping and mold filling, enabling the production of complex or intricate glass designs with accurate dimensions and details.

Quality control and consistency: The gob drop process facilitates quality control by providing a specific starting point for the glass forming process. Manufacturers can monitor and adjust the gob drop parameters to ensure consistent product quality, reducing variations and defects.

Overall, the gob drop process in glass manufacturing offers advantages in terms of controlled glass distribution, improved product quality, production efficiency, waste reduction, flexibility, and quality control. These advantages contribute to the production of high-quality glass containers or bottles while optimizing resources and enhancing manufacturing capabilities.

English

English 中文简体

中文简体

dipper.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

dipper.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

dipper.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

dipper(2).jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

dipper.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

Jul 23,2024

Jul 23,2024

+86-575-87637902

+86-575-87637902 +86-13606564271

+86-13606564271

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China