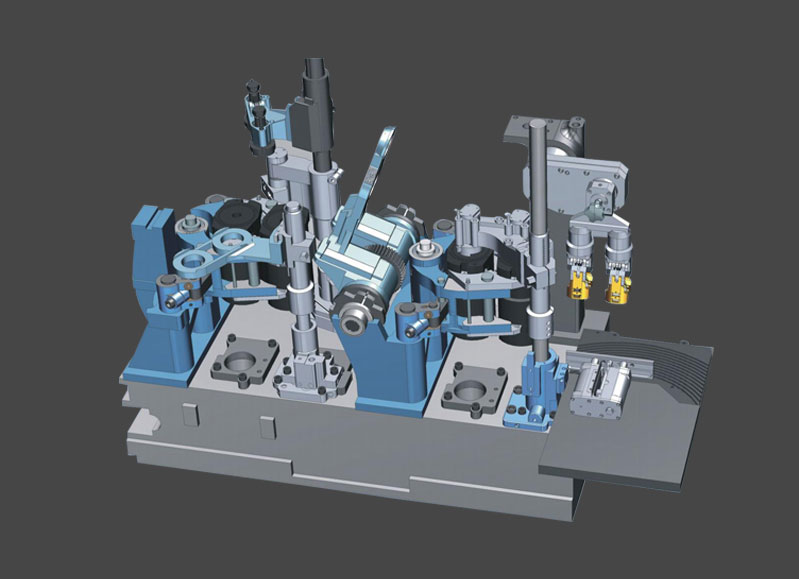

The blow head arm is a mechanical or robotic arm that is part of a blow molding machine. Its primary function is to precisely position the blow head or blow pin within the mold cavity during the blow molding process. The blow head is responsible for introducing compressed air or other gases into the parison to inflate it and shape it against the mold walls.

The blow head arm is designed to move the blow head in and out of the mold cavity at the appropriate times. It ensures that the blow head is correctly positioned to achieve the desired wall thickness and shape of the blown part. The arm may have adjustable settings for controlling the movement, timing, and pressure of the blow head to achieve consistent and high-quality blow-molded products.

By controlling the position and movement of the blow head, the blow head arm contributes to the overall precision and repeatability of the blow molding process, resulting in accurate and consistent part dimensions and characteristics.

In summary, the blow head arm is a component of a blow molding machine that holds and positions the blow head or blow pin. It ensures proper placement and movement of the blow head during the blow molding process to achieve the desired shape and quality of the final blow-molded parts.

Choosing the right

blow head arm for a blow molding machine involves considering several important factors. Here are some key points to consider when selecting a blow head arm:

Machine compatibility: Ensure that the blow head arm is compatible with the specific blow molding machine you are using. Consider factors such as the machine's size, configuration, and design requirements to ensure a proper fit and functionality.

Application requirements: Evaluate the specific requirements of your blow molding application. Consider the size, shape, and material of the parts you are producing. Determine the desired blow head movement and positioning needed to achieve the desired part dimensions, wall thickness, and quality.

Adjustability and precision: Look for a blow head arm that offers adjustability and precise control. It should allow for fine-tuning of parameters such as blow head position, timing, and pressure. This adjustability helps optimize the blow molding process and ensures consistent results.

Durability and reliability: Choose a blow head arm made from high-quality materials that can withstand the demands of the blow molding process. It should be robust, durable, and resistant to wear and tear. Consider the arm's construction and any additional features that enhance its reliability and longevity.

Ease of operation and maintenance: Select a blow head arm that is user-friendly and easy to operate. It should offer intuitive controls and interfaces for adjusting parameters and monitoring the blow head's position. Additionally, consider maintenance requirements and access for cleaning, lubrication, and potential repairs.

Cost considerations: Consider the cost-effectiveness of the blow head arm. Evaluate the upfront investment, long-term durability, and potential savings in terms of improved productivity, reduced downtime, and overall quality of the blow-molded parts. Find a balance between quality and cost that fits your specific requirements and budget.

By carefully considering these factors, you can choose a blow head arm that is compatible with your blow molding machine and meets the specific requirements of your application. This will help optimize the blow molding process, achieve consistent part quality, and improve overall production efficiency.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

Nov 22,2024

Nov 22,2024

+86-575-87637902

+86-575-87637902 +86-13606564271

+86-13606564271

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China