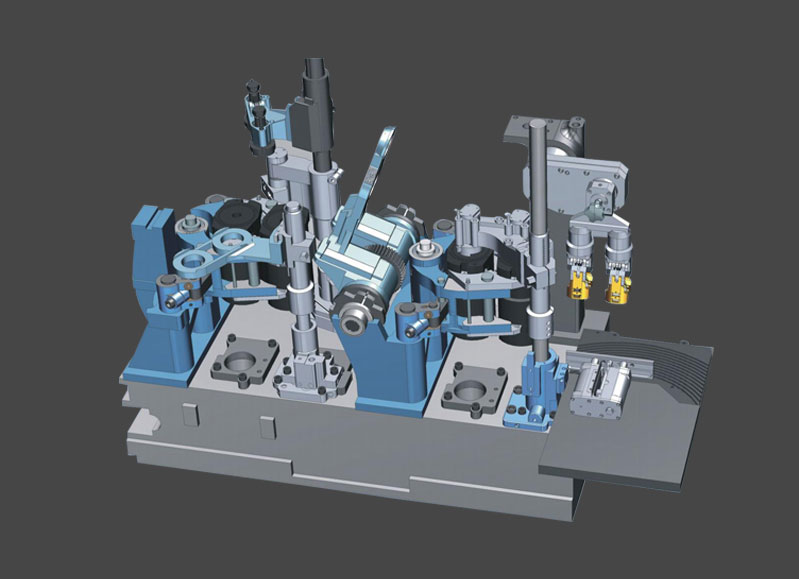

“Take-out arm belt drive" refers to a mechanism used in industrial automation systems, particularly in the field of manufacturing or packaging. It involves using a belt drive system to operate the take-out arm, which is responsible for picking up or removing objects from a specific location or conveyor.

The take-out arm is a mechanical device that typically consists of a robotic arm or a similar mechanism designed to perform automated tasks. It is commonly used in assembly lines, packaging lines, or material handling systems to transfer products or components from one stage to another.

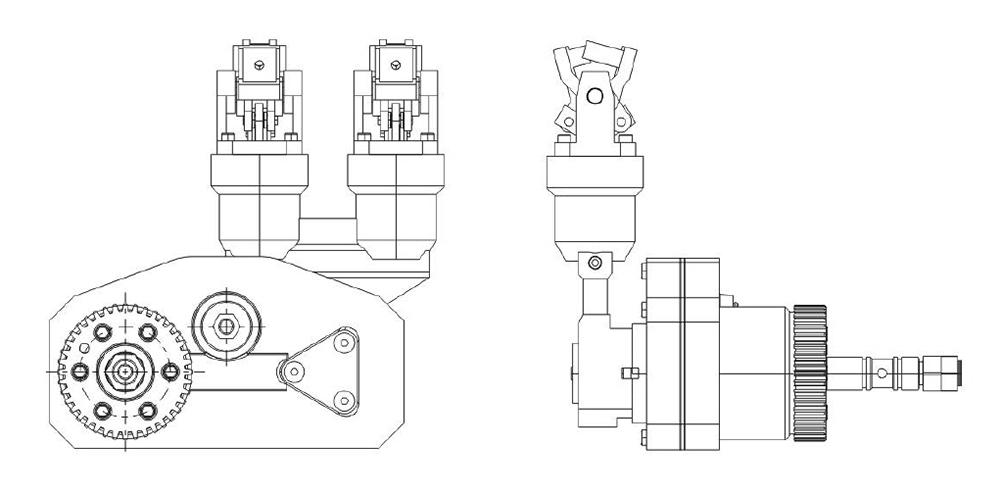

In a take-out arm belt drive system, a belt drive mechanism is employed to control the movement of the take-out arm. The belt drive system typically consists of a belt (usually made of materials such as rubber or polyurethane), pulleys, and a power source such as an electric motor.

The belt is looped around the pulleys, and the motor provides the driving force to move the belt, which, in turn, moves the take-out arm. By controlling the speed and direction of the motor, the belt drive system controls the movement of the take-out arm in a precise and controlled manner.

The use of a belt drive system in a

take-out arm offers several advantages. It provides smooth and continuous motion, allowing for precise positioning and controlled movement of the arm. The belt drive system is also relatively quiet, efficient, and requires minimal maintenance compared to other drive mechanisms.

Additionally, the belt drive system enables flexibility in terms of adjusting the speed and acceleration of the take-out arm's movement. This adaptability is beneficial in various manufacturing or packaging applications where different speeds or positioning requirements may be needed.

Overall, the take-out arm belt drive system is a mechanism that utilizes a belt drive to control the movement of a take-out arm in industrial automation systems. It offers precise, smooth, and efficient operation, contributing to improved productivity and automation capabilities in manufacturing or packaging processes.

The use of a take-out arm belt drive system in industrial automation offers several advantages. Here are some key advantages of utilizing a take-out arm belt drive:

Precise and controlled movement: A belt drive system allows for precise positioning and controlled movement of the take-out arm. The belt drive mechanism enables smooth and accurate motion, ensuring the arm can pick up or remove objects with precision, minimizing errors or damage.

Smooth and continuous operation: The belt drive system provides smooth and continuous operation of the take-out arm. The belt's flexibility and the absence of jerky movements ensure consistent motion, reducing the risk of product or component mishandling or disruption to the production process.

Quiet and efficient: Belt drives are generally quiet during operation, resulting in a quieter working environment. Additionally, they offer high efficiency as they can transmit power efficiently from the motor to the take-out arm, minimizing energy losses.

Minimal maintenance: Belt drives require relatively low maintenance compared to other drive mechanisms. They have fewer moving parts, reducing the need for frequent lubrication or replacement of components. This translates to lower maintenance costs and less downtime for maintenance activities.

Adjustable speed and acceleration: Belt drives offer flexibility in adjusting the speed and acceleration of the take-out arm's movement. This adaptability is advantageous in manufacturing or packaging processes where different speeds or positioning requirements may be necessary. The ability to adjust the drive parameters allows for optimized performance and increased productivity.

Cost-effective: Belt drives are generally cost-effective compared to alternative drive systems. They are relatively simple in design and construction, making them more affordable to implement and maintain. The lower cost of belt drives can contribute to overall cost savings in automation systems.

Wide range of applications: Take-out arm belt drive systems can be utilized in various industrial applications. They are suitable for assembly lines, packaging lines, material handling systems, and other automation processes where precise and controlled movement of objects is required.

Overall, the advantages of a take-out arm belt drive system include precise and controlled movement, smooth operation, quietness, efficiency, low maintenance requirements, adjustability, cost-effectiveness, and versatility in application. These advantages contribute to improved productivity, accuracy, and reliability in industrial automation processes.

English

English 中文简体

中文简体

.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

May 02,2024

May 02,2024

+86-575-87637902

+86-575-87637902 +86-13606564271

+86-13606564271

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China