In the context of glass container manufacturing, a neck ring mechanism refers to a component or assembly used in the glass forming process.

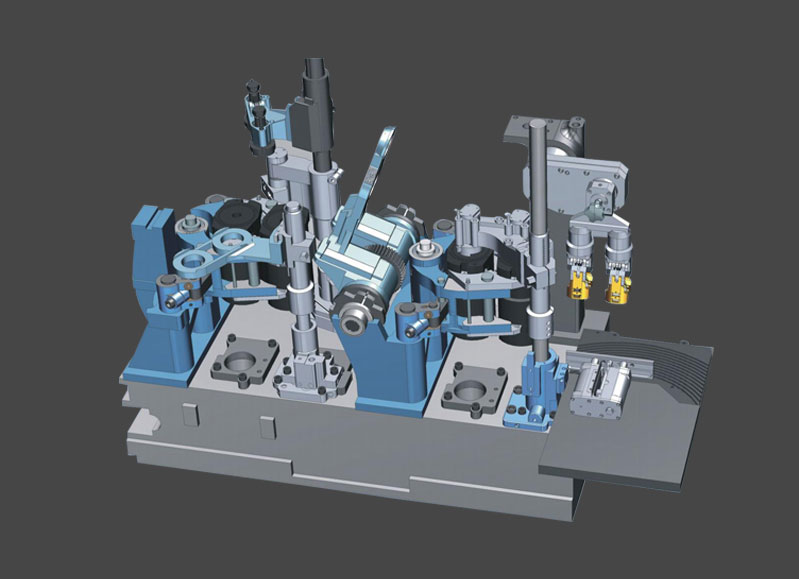

When glass containers, such as bottles or jars, are manufactured, a neck ring mechanism is used to shape and form the neck and finish of the container. The neck ring mechanism consists of various components, including the neck ring itself, which is typically made of metal.

The neck ring mechanism is positioned around the parison (a molten glass blob) while it is being formed and shaped by the glass forming machine. As the parison is pressed and blown into the desired container shape, the neck ring applies pressure and forms the neck and finish of the container. The neck ring plays a crucial role in defining the dimensions, thickness, and design of the container's neck.

The neck ring mechanism may also include other elements, such as a blowhead or blowpipe, which introduces compressed air into the parison to inflate and shape it against the mold.

The design and configuration of the neck ring mechanism may vary depending on the specific container shape and manufacturing process. It is essential for ensuring the accurate and consistent formation of the neck and finish of glass containers during the glass forming process.

The features of a neck ring mechanism in glass container manufacturing can vary depending on the specific design and configuration. However, here are some common features and characteristics:

Material: Neck rings are typically made of durable materials such as metal alloys, such as stainless steel or bronze. The material is chosen for its resistance to heat, wear, and corrosion, as well as its ability to withstand the forces and pressures involved in the glass forming process.

Shape and dimensions: The neck ring is designed to match the desired shape and dimensions of the container's neck and finish. It may have a specific contour, profile, or taper to achieve the desired appearance and functionality of the container.

Adjustability: Neck ring mechanisms often offer adjustability to accommodate different container sizes, shapes, and designs. They may have mechanisms for adjusting the position, height, or diameter of the neck ring to ensure proper alignment and control during the glass forming process.

Cooling system: In some cases, neck ring mechanisms may incorporate a cooling system to help regulate the temperature of the neck ring. The cooling system can help dissipate heat and maintain consistent temperatures, preventing overheating or thermal deformation of the neck ring.

Mounting and attachment: Neck ring mechanisms are designed for easy installation and removal from the glass forming machine. They may include mounting features such as clamps, bolts, or quick-change mechanisms for efficient mold changes and maintenance.

Wear resistance: Due to the high temperatures and mechanical stresses involved, neck rings are often engineered with wear-resistant properties. They may have hardened surfaces or coatings to withstand the abrasive nature of the glass forming process and prolong their lifespan.

Precision and reliability:

Neck ring mechanisms must provide precise and reliable shaping of the container's neck and finish. They are designed to apply consistent pressure and control the forming process to ensure uniformity and accuracy in the final product.

These features collectively contribute to the proper formation and shaping of the neck and finish of glass containers during the glass forming process. The neck ring mechanism plays a crucial role in achieving the desired container dimensions, aesthetics, and functionality.

English

English 中文简体

中文简体

-1.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

May 02,2024

May 02,2024

+86-575-87637902

+86-575-87637902 +86-13606564271

+86-13606564271

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China