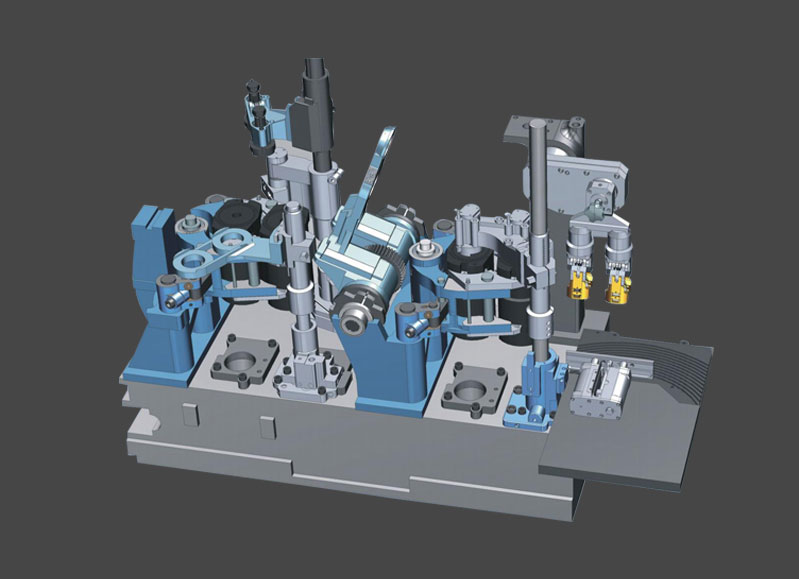

A take-out arm, also known as a pick-and-place arm or robotic arm, is a mechanical device used in industrial automation systems to perform the task of picking up or removing objects from a specific location or conveyor and placing them in another desired location.

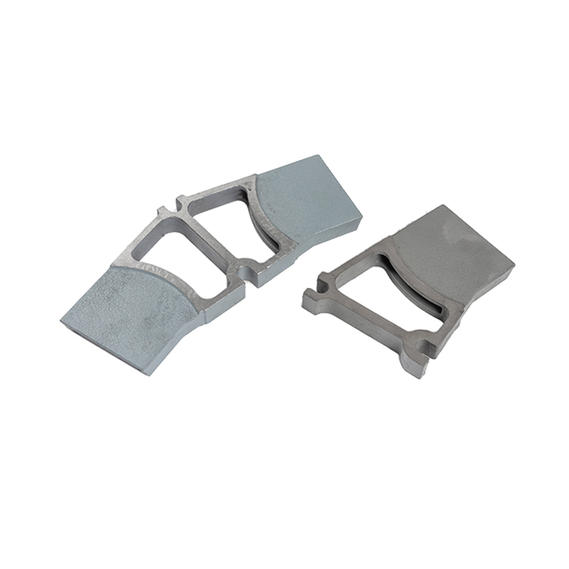

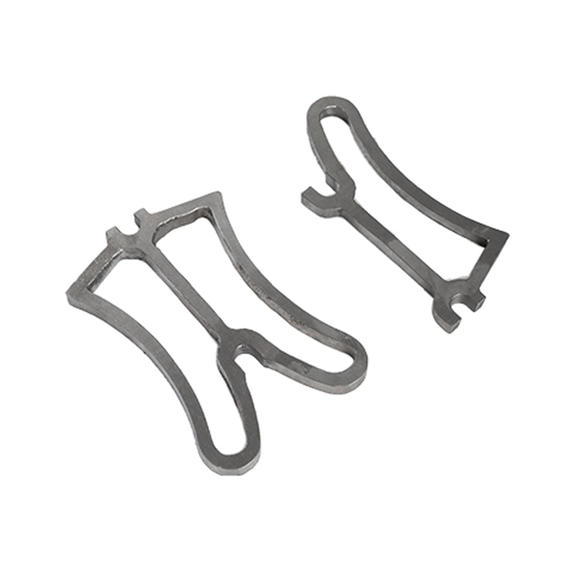

The take-out arm is typically equipped with various components such as joints, links, grippers, and sensors, allowing it to mimic the movement and functionality of a human arm. It is often designed to be programmable and can be controlled manually or automated using computer software.

The primary purpose of a take-out arm is to automate the process of handling objects in manufacturing, assembly, or packaging operations. It can be used to transfer products or components from one stage to another, load or unload materials, or perform precise placement tasks with accuracy and efficiency.

Take-out arms are commonly used in industries such as automotive manufacturing, electronics, food and beverage, pharmaceuticals, and logistics, where repetitive or intricate object handling tasks are involved. They offer advantages such as increased productivity, improved precision, reduced manual labor, and enhanced safety.

The functionality and capabilities of take-out arms can vary depending on the specific application and requirements. Some take-out arms are designed to perform simple pick-and-place operations, while others are more advanced and can handle complex tasks with multiple degrees of freedom and sensor integration for object recognition or quality control.

Take-out arms can be integrated into larger automation systems or standalone units depending on the needs of the application. They can be programmed to follow specific paths or sequences, and their movements can be synchronized with other components of the production line for seamless operation.

Overall, the take-out arm is a versatile and essential component of industrial automation systems, providing efficient, accurate, and reliable object handling capabilities in various industries.

Proper maintenance of a take-out arm is essential to ensure its optimal performance and longevity. Here are some maintenance tips for a take-out arm:

Regular cleaning: Keep the take-out arm clean and free from dirt, dust, and debris. Wipe down the surfaces using a soft cloth or brush. Pay attention to areas where dust or debris can accumulate, such as joints and crevices.

Lubrication: Check the manufacturer's recommendations for lubrication requirements. Apply lubricants as specified to the moving parts and joints of the take-out arm to ensure smooth operation. Use the appropriate lubricant recommended by the manufacturer.

Inspection and adjustment: Regularly inspect the

take-out arm for any signs of wear, damage, or misalignment. Check for loose screws, bolts, or connections and tighten them as necessary. Ensure that all components are properly aligned and functioning correctly.

Replace worn or damaged parts: Over time, certain parts of the take-out arm may wear out or become damaged. Replace any worn or damaged components promptly using genuine replacement parts provided by the manufacturer. Follow the manufacturer's instructions for part replacement or seek professional assistance if needed.

Electrical connections and cables: Inspect the electrical connections and cables of the take-out arm. Ensure they are secure, free from damage, and properly insulated. Check for any signs of fraying or exposed wires and address them immediately to prevent electrical hazards.

Sensor calibration: If the take-out arm utilizes sensors for object recognition or positioning, periodically check and calibrate the sensors as per the manufacturer's instructions. This ensures accurate and reliable operation during the pick-and-place tasks.

Safety checks: Ensure that all safety features and emergency stop buttons are functioning properly. Test and verify their operation regularly to maintain a safe working environment for operators and prevent accidents.

Documentation and records: Keep a maintenance log or record of maintenance activities, including dates of inspections, lubrication, repairs, and parts replacements. This documentation can help track the maintenance history and schedule future maintenance tasks.

Professional servicing: If you encounter any complex issues or if the take-out arm requires extensive maintenance or repairs, it is advisable to contact the manufacturer or a qualified service technician for assistance. They have the expertise and knowledge to diagnose and address any technical problems.

English

English 中文简体

中文简体.jpg?imageView2/2/w/569/h/569/format/jp2/q/75)

May 02,2024

May 02,2024

+86-575-87637902

+86-575-87637902 +86-13606564271

+86-13606564271

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China

No. 20, Sanfeng Road, Diankou Town, Zhuji City, Zhejiang Province, China